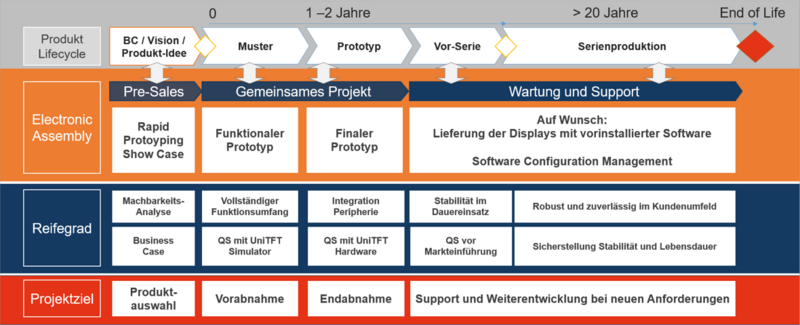

Efficient programming already for the first sample application. We create a small test application for you free of charge and you can fully concentrate on your core competence in the meantime. As soon as you have a specification, we will gladly prepare an offer for the implementation. In mass production, we also deliver our displays pre-installed with your individual software "onboard" ex works on request. The smaller the quantities of your products, the greater the advantage. Learn more about our comprehensive service here:

- Company

- Products

- HMI Series

Modbus - uniTFT(s)

High-End PCAP - PLC Compact Controller

w. Touch - Software Service

uniTFT and eDIP - eDIPTFT

Serial TFT - DIP

Direct mounting - DOG

The versatiles - OLED

New technology - TFT / Graphic

color and b&w - Dotmatrix

Textdisplays - USB / RS-232

DISPLAYS - KIT

Control panels - DVM Counter

Panelmeter - Data Logger

USB / Wifi - Accessories

- HMI Series

- Support

- News

- Contact

- Career

- Shop

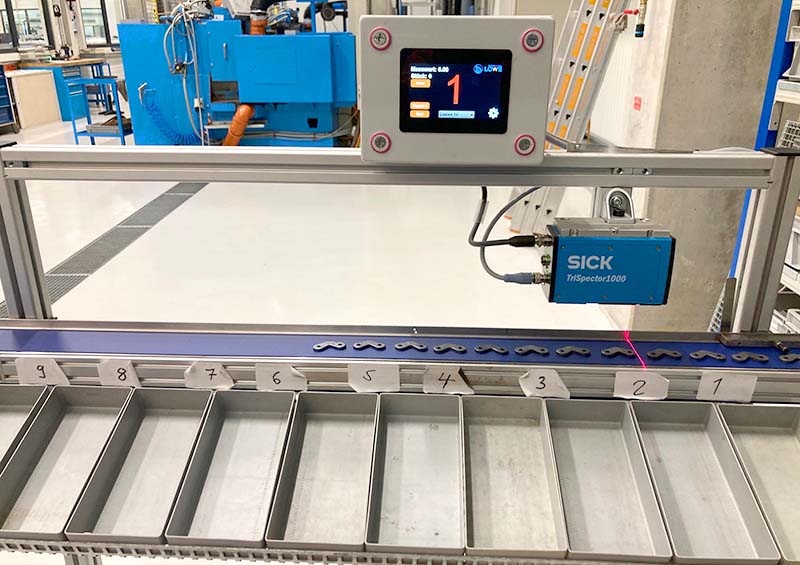

![[Translate to Englisch:] Jäger Handling visu-box [Translate to Englisch:] Jäger Handling visu-box](/fileadmin/html-seiten/images/softwareservice/Jaeger_visu-box.png)