"Resistive" stands for the measurement method, i.e. the measurement of a resistance and "responding to pressure".

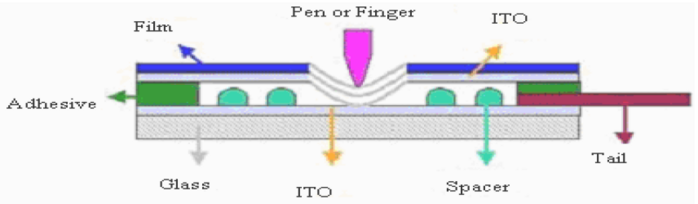

The structure of this technology consists of two layers, usually a deformable polyester film and a rigid glass substrate. The inner sides are each coated with a thin, translucent metallization (usually indium tin oxide). In order to avoid short circuits, both layers must be kept at an even distance with so-called spacers.

If the deformable layer is now pressed from the front, contact is made with the lower layer. The position can be determined by measuring the resistance.

Measurement method:

A DC voltage is applied to one of the two plane layers, e.g. the upper one. In the non-pressed state, no voltage can be measured at the other layer.

If the two conductive layers are now pressed together at a certain point, a voltage is measured which is linear to the position of the pressure point. This allows a direction to be determined, e.g. the X-direction. In a second measuring process, a voltage is again applied, only this time to the other layer (e.g. the lower one). A voltage measurement at the other layer (top) allows a conclusion about the position in Y-direction.

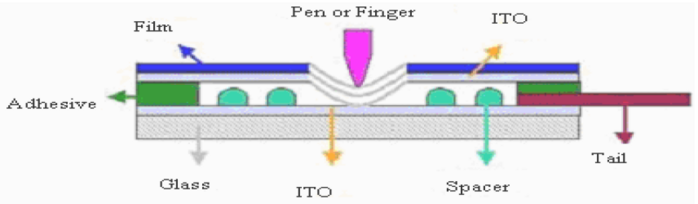

In contrast to PCAP (capacitive touch panels), resistive touch panels are much more reliable in their response behavior. Where with PCAP (cell phone etc.) you sometimes try a second or third time "to hit a key", the resistive touch panel reacts immediately - provided that the corresponding evaluation is done. We have summarized further differences in a table below.

![[Translate to Englisch:] Touchpanel resistiv und kapazitviv, Unterschiede und Vorteile [Translate to Englisch:] Touchpanel resistiv und kapazitviv, Unterschiede und Vorteile](/fileadmin/images/header/produkte/Header_Touchpanel_1280x427.jpg)

![[Translate to Englisch:] Inbtelligente Touchpanel, HMI oder Standard IPS Panel mit RGB oder reine Konpnenten zum Nachrüsten oder als Ersatz [Translate to Englisch:] Inbtelligente Touchpanel, HMI oder Standard IPS Panel mit RGB oder reine Konpnenten zum Nachrüsten oder als Ersatz](/fileadmin/html-seiten/images/support/Touch_weiterfuehrende_Links.jpg)